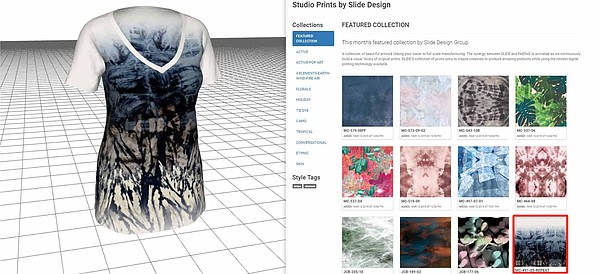

Los Angeles companies Tukatech, the fashion-technology firm, and FABFAD, the digital microfactory, have announced their partnership that affords access to more than 100,00 unique fabric prints designed and sourced by FABFAD to users of TUKA3D Designer Edition. Image: Tukatech

MICROFACTORY

Tukatech and FABFAD Announce Collaboration

Fashion-technology provider Tukatech, and FABFAD, the Los Angeles-based digital and full-service microfactory, have announced a collaboration that connects TUKA3D Designer Edition to more than 100,00 unique fabric prints designed and sourced by FABFAD. Using 3D technology, designers will be able to visualize fabric prints on a 3D garment, then have the approved sample made in real life.

Designers will be able to access FABFAD’s proprietary print library and develop 3D samples using TUKA3D Designer Edition. TUKA3D allows for users to visualize fabrics and trims in 2D or 3D before making a physical sample, helping to reduce waste during the sampling process. Once the digital look or collection is created, users will be able to order sample or production yardage directly from FABFAD. Users can access Tukatech’s library of ready-made 3D garments or find a specific model they want to design for, then shop styles made for that model.

“The process allows for designers to visualize their new styles and concepts in 3D and with the assurance of those actual fabrics and prints being available to them at any quantity they wish,” Chris Walia, chief operating officer at Tukatech, said.

Tukatech has also partnered with Sowtex, a B2B textile marketplace, that established a connection between TUKA3D users and over 10,000 textile manufacturers, cutting sampling turnaround time from weeks to hours.

FABFAD is a Tukatech Communal Microfactory providing complete design, development, and manufacturing space for rent. Offerings include workspace, meeting rooms, 2D and 3D CAD systems, sample making, and cut and sew to finished product. FABFAD has the largest selection of fabrics for digital sublimation printing and direct-to-fabric printing with hundreds of trending and high-quality fabrics.