The Silq platform allows ease along the supply chain, as brands are in direct contact with an agent who manages production overseas.

TECHNOLOGY

Silq Smooths Out Transparency Issues Within the Apparel Supply Chain

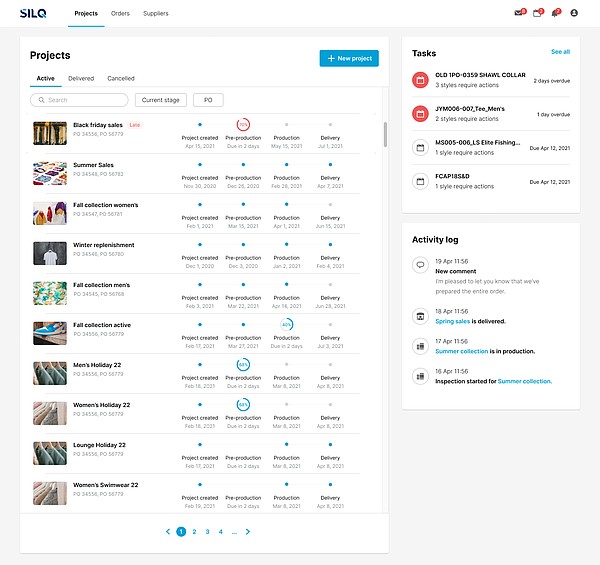

Supply-chain management continues to evolve and, at the forefront of that evolution, San Jose, Calif.’s Silq leads the way. Founded in March 2020 by Ram Radhakrishnan, the company’s chief executive officer, and Kate Alexander, vice president of operations, the company serves as a manager of production, extending the reach of a client brand’s sourcing and merchandising abilities by utilizing the expertise of local industry professionals in India; Guangzhou, China; and Ho Chi Minh City. Through utilizing its platform, which aggregates data directly from Silq agents on the factory floor, the company allows brands to see in real time the status of their goods throughout the production process.

“The platform that we’ve built gives the customer complete visibility from the time you place a purchase order to the process in a sample-development phase through the production phase,” Radhakrishnan said. The traditional model leaves a lot of room for error considering the amount of time products spend inside the factory.

“Products spend 90 to120 days going from concept to delivery. The last 30 to 45 days is when it shifts from a factory to a consumer’s hand,” Radhakrishnan said. “If you look at it from that perspective, 70 percent of a product’s journey inside the supply chain happens inside of a factory.”

As alumni of San Francisco freight forwarder Flexport, Radhakrishnan and Alexander wanted to create a service that would increase transparency along the supply chain. Bringing on fellow Flexport alum Vishnu Nair—with whom Radhakrishnan attended engineering classes in India—as Silq’s chief technology officer, the new platform allows brands to use the data that is shared by their on-site factory agents in order to keep their supply chains moving or easily shift when issues arise. These agents, according to Radhakrishnan, are seasoned professionals, some with 20 or 30 years of experience.

“Somebody is there regularly following up on production processes, inspecting the fabric and top sample as the merchandise is being produced, giving visibility throughout the production process,” Radhakrishnan explained. “If the production is going to be delayed, you can adjust your forecast accordingly, you can notify every other stakeholder within the supply chain so they can be prepared for what is coming.”

Whitney Murillo, director of global sourcing at Irving, Texas’s Pinpoint Merchandising views Silq as invaluable. Professional relationships forged with Silq’s agents, such as Manasi, Raj and Sundar in India, lend personal touches to business, as these representatives have the industry connections and intuition to anticipate Pinpoint’s needs, often saving precious days during production.

“They have added that value and efficiency to the process by having their team members onsite to catch issues or communicate questions in real time and problem solve,” Murillo explained. “On one order, Manasi stepped up and said ‘I have a supplier for that trim that you’re struggling with, do you want me to reach out to them?’ She helped solve that issue. No conflicts arose.”

Named after the Silk Road and the luxurious qualities of silk fibers, Silq aims to afford a smooth process along the supply chain, according to Radhakrishnan. Unlike the premium cost of silk, Silq’s services are provided at a reasonable price. With packages available under $300, Radhakrishnan likes to position Silq’s pricing at $.10 per unit or “less than the cost of sewing a button on a shirt.”

“There is a way for you to achieve transparency in the supply chain without paying a significant premium for it,” Radhakrishnan said. “For ages, brands had to rely on sourcing agencies, buying houses, paying a significant premium—upwards of 10 percent—to agents to help source and manage production overseas. In this day and age of technology, that should not be the case.”