TINCTORIUM’S ECO INDIGO

Tinctorium’s Natural Indigo Dye Receives Help From the Godfather of Denim

Michelle Zhu and Tammy Hsu, co-founders of San Francisco–based Tinctorium, are entering the apparel supply chain with a revolutionary natural product projected to transform sustainable indigo-dyeing methods in denim manufacturing.

“Current chemical synthesis of indigo involves dangerous chemicals such as formaldehyde, cyanide and petroleum. For every kilogram of indigo, over 100 kilograms of petroleum are used to produce that small, incremental unit,” Zhu explained. “Indigo isn’t water soluble. To apply indigo as a dye, a chemical-reducing agent, which is also a water pollutant, must be added.”

The women launched their company earlier this year after bioengineering PhD candidate Hsu identified a naturally occurring enzyme she wanted to use as a research marker during her thesis coursework at the University of California, Berkeley.

She discovered that this microbe-created pigment could be used as an indigo alternative to toxic synthetic dyes. The pigment could also be applied in a water-soluble state by adding an enzyme that finalized this natural dyeing process.

While Chief Executive Officer Zhu and Chief Scientific Officer Hsu might seem to be unlikely fashion entrepreneurs, they do have a connection to the Los Angeles apparel industry. For the last 20 years, Zhu’s parents have owned Vibes Base, an El Monte, Calif., garment-development company.

“This was a new opportunity where Tammy needed someone with a business background,” said Zhu, a graduate of the Olin Business School at Washington University in St. Louis. “The more we talked about it and discussed my family’s background in the apparel industry, it felt perfect and serendipitous to us.”

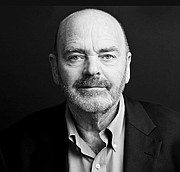

Growing in popularity at a rapid pace, Tinctorium’s technology is now supported by the denim industry’s sustainability master. Through a network of sustainable-apparel technology professionals, Zhu and Hsu were introduced to Adriano Goldschmied, the godfather of denim, who is dedicated to creating cleaner, safer and ecologically sound denim-manufacturing practices. On May 9, he was named Tinctorium’s denim innovation adviser.

“From the beginning of my first conversation with him, it was clear Adriano wants to do things right and he cares a lot about openness,” Zhu said. “He understands the patience needed to develop a big change in technology.”

For Goldschmied, who currently leads the Los Angeles–based development organization House of Gold, learning about Tinctorium’s technology was groundbreaking. Working with science-based solutions is a shift he welcomes in his mission to clean up the denim industry.

“When I met Michelle, she explained the concept and—after half an hour—I knew I needed to join them,” he said. “Our industry has not always been very scientific, but the connection with authentic research brings the industry to a different level. We live in an era where we have to contribute to fashion from the aesthetic point of view but also the substantial point of view.”

Through House of Gold, Goldschmied is developing Tinctorium-dyed fabric with Blue Diamond, a mill located in China’s Hebei province. The sustainable-denim mission he has embarked on has led Goldschmied to develop a mindset by which he believes making an impact is only possible through mass-market distribution of ecologically produced jeans.

“The final destination of this process is going to be Asia,” he said. “It’s a region where they produce more jeans than any other place—whether it’s China, Vietnam, Bangladesh or Pakistan. It’s a place where we need to be when we have an industrial solution.”

By the end of June, Tinctorium will complete its demonstration day at the San Francisco science-based startup incubator called Indie Bio, which is similar to a graduation for the company. Within the next few months, Goldschmied said he will be ready to begin fabric testing.

“We have the capacity to produce one kilogram of indigo every two weeks. We are starting to make fabric with the dyeing process,” he said. “Then we will make the first jeans with the bio indigo. It is a revolution.”

Currently, the Tinctorium team is navigating the manufacturing process and anticipates its products will hit the market by 2021. Once the technology is ready, Zhu sees adoption of Tinctorium technology by denim manufacturers as an easy transition.

“One of our advantages is that we see this as an easy plug-in solution for the supply chain,” she said. “It’s not something that requires a ton of additional investment into a lot of new capital and machines.”

In order to maximize the reach of Tinctorium and revolutionize the way the apparel industry produces denim, Zhu hopes to begin with capsule collections through premium-denim-brand partnerships.

“We are actively looking for partnerships with brands to incorporate a more sustainable solution into their solutions,” she said. “We would love to launch lines with brands who are interested in creating a more sustainable pair of jeans.”