TECHNOLOGY

Epson’s Latest Printer Aims for High-Speed Production Users

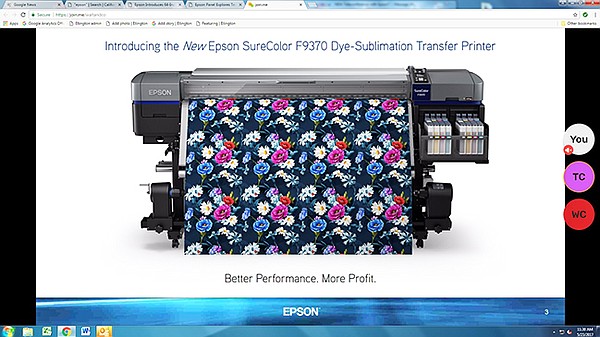

Epson America, the Long Beach, Calif.–based U.S. division of Japanese print technology company Seiko Epson Corp., has a new wide-format printer for dye-sublimation transfers that is designed to provide the speed and accuracy needed for medium- and high-volume printing.

“This is a very high-production printer with speeds of more than 1,000 square feet an hour,” said Tim Check, Epson America’s product manager for professional imaging.

According to the company, the 64-inch Epson Sure–Color F9370 can deliver industrial-level production speeds up to 1,169 square feet per hour. The printer has several features to ensure hands-off accuracy at high print speeds. For example, the F9370 has a new integrated fabric wiping system that cleans the printhead to ensure that paper fibers don’t get stuck to the printhead plate.

Check compares the wiping system to the old-fashioned hand dryers with a loop of fabric that feeds a fresh section of fabric for each use.

“Inside one of these fabric wipers is about 50 feet of fabric wiping fabric—enough to last a standard user about four to six months,” he said. “Every time it wipes the head, it pulls up a new fresh piece of pristine fabric.”

The wiping system cuts down on the need for user intervention, Check said.

“During a long print or overnight print, the printer can automatically wipe the printhead during the middle of print and then resume printing. It only takes a few seconds to do,” he said.

There is a roll-to-roll media support system with automatic paper-tension controls to consistently feed the paper through the printer. The feeder supports a range of paper and roll sizes and is able to handle everything from fabric production to soft signage and home décor applications. The heavy-duty frame is factory aligned and doesn’t require manual adjustment, Check said.

“Our take-up reel also has a capacity up to 100-pound rolls,” he said. “The grip roller is designed to handle heavy-weight papers all the way down to as light as 40-gram paper. Being able to handle heavier rolling means you can put more paper on the roll to be more productive. If you’re going to print overnight, you can load the printer up. Instead of having a 500-foot roll you may be able to go up to a 1,000-foot roll. That really can boost up your overall throughput for one of these machines.”

At high printing speeds, getting the tension wrong between the two rollers can result in a light band or a dark band running across the print. The F9370 has a large feed roller that helps control the speed that the paper runs through the printer.

“At the beginning of the roll, there’s more weight on the roll. The printer needs a little more power to overcome the inertia of the paper,” Check said. “When you’re at the end of the roll, the roll is pretty light and it’s easier to turn. This big grip roller gives us more precise control.”

The printer also has sensors in the paper unwinder, the take-up system and the media-feed roller, which all work together to ensure the proper power, torque and tension are applied at all times during printing.

“All that is done in real time,” Check said. “The sensors are communicating as the printer is in motion.”

The dual-printhead F9370 uses UltraChrome DS Ink technology, which delivers high-density blacks, high contrasts and good color saturation. The printer has a high-capacity ink tank that can hold up to three liters of ink per color. The printer has a micro-weaving function to determine how many printhead passes are needed to blend the colors when putting the ink on Epson DS Transfer Papers. Like Epson’s other printers, the F9370 uses Wasatch SoftRIP TX software.

“This is a total turnkey solution,” Check said. “All that’s needed is a heat press and the fabrics.”

The printer is managed from the Epson Control Dashboard, which can run cleanings remotely, check ink levels, update firmware and download new media profiles.

Check said he anticipates many of the customers that purchase the F9370 are also using earlier F-Series printers and will continue to use the older models after they add the F9370. These customers need assurance that print color and quality will be consistent from printer to printer.

“That’s a big factor, especially when you’re producing apparel where you have a small-size dress on one printer and a medium-size dress on the other. They’re coming off two different printers but they have to look the same if they’re going to go on the same rack,” Check said.

The SureColor F9370 is replacing the SureColor F9200 and joins a portfolio of SureColor F-Series printers, which includes the SureColor F6200 and SureColor F7200. The F9370 is designed to meet the needs of high-volume producers looking for speed, accuracy and quality with little need for much user intervention.

“All those applications that you can do with dye sublimation, you can still continue to do—you can just do them more efficiently,” he said.