TECH WEST: Techtextil, organized by Messe Frankfurt, was held March 19–21 at the Anaheim Convention Center.

TECHNOLOGY

Technical Textiles and Equipment Converge at Techtextil and SPESA in Anaheim, Calif.

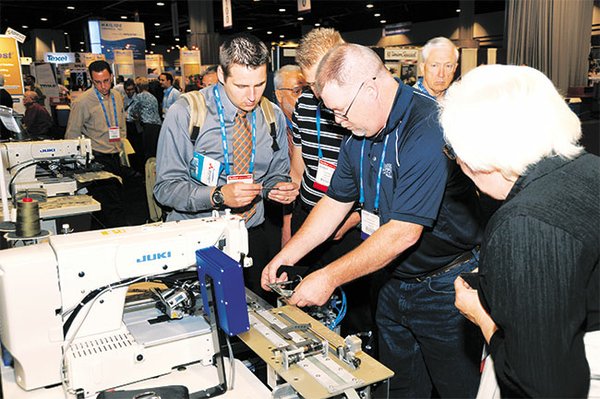

The international Techtextil North America trade fair, in conjunction with The Sewn Products Equipment & Suppliers of the Americas (SPESA), was held March 19–21 at the Anaheim Convention Center in Anaheim, Calif., where technical textiles, nonwovens and functional-apparel makers displayed new and innovative machinery and materials.

“Fifteen years ago or so, there was a lot of manufacturing in this country for textiles, but now it is more high-tech textile products with different types of fibers and composite materials, like carbon fiber woven materials,” said Erik Wittenzellner of Zwick USA, the Kennesaw, Ga.–based U.S. division of German machinery maker Zwick/Roell Group, which produces machinery for compression testing, tensile testing and seam-slippage resistance.

The market is changing, Wittenzellner said.

“[In the past,] we had a niche market in Lyrca and spandex [for] intimate apparel and workout apparel,” he said. “Now, we have needs for higher-strength and performance materials that have a lot of physical and chemical properties in them.”

Gehring Textiles, a family-run domestic mill based in Garden City, N.Y., with facilities in upstate New York, has been in business for more than 70 years, manufacturing stretch wovens and circular knits. The company’s diverse customer base specializes in products for the military, aerospace and automotive industries, as well as intimate apparel and upholstery makers.

“Four years ago, during the recession—when it almost killed the textile trade—people were going out of business,” said William P. Christmann, a Gehring representative. “The overheads were so top heavy, and costs were going up because [prices for] every fiber—from nylon to polyester—went up. People went out of business unless they had a specialty-niche capability.”

In particular, Gehring supplies U.S.-based technical textiles for personal-protection markets such as fire protection, cut resistance, impact absorption and engineer driven, said Christmann, who added that U.S.-made products can command a higher price.

Efficiency and ‘Made in America’

Maximizing efficiency and improving productivity to offset the cost of domestic production was among the talk at SPESA’s concurrent conference for apparel manufacturers looking for information about new technologies and techniques for the factory floor.

Michael T. Fralix, president and chief executive officer of TC2, based in Cary, N.C., said the SPESA program was designed to focus on quality and efficiency improvements and reduction of lead time in the manufacturing sector. “So we are reviewing cutting-and-sewing technology, addressing material handling and better managing tools for products.”

Fralix said there has been “tremendous” talk about production returning to the United States. “In Los Angeles, there is already a strong base for domestic production, so they are already one of the leaders in the U.S., but companies are [still] looking at what are the things that are going to drive the decision where the product gets made,” he said.

French machinery and software maker Lectra was one of the presenters at the SPESA conference. Paul Epperson, Lectra vice president of sales, discussed the integration of technology solutions, specifically Lectra’s automated cutting techniques, and the concept of “change” on the cutting floor.

“There is a rebirth in the cutting room with an intensity to make improvements,” Epperson said. Maximizing efficiencies in the cutting room can offset rising fabric costs.

However, “everyone is on a different journey with automation, but the want to produce quality products is still there,” he said.

Creative tools and software can build efficiency, but Epperson stressed that analytics or Overall Equipment Efficiency (OEE) is necessary in order to evaluate why a company should turn to automated cutting.

According to Epperson, fabric can be anywhere from 50 percent to 75 percent of the cost of products, so companies should question if the automation software will help with improvement and eliminate over-consumption of fabric.

Other ways new technology can improve the production process include increasing capacity, optimizing space and reducing costs.

The right tools—such as proactive and predictive maintenance and real-time support—can maximize “uptime,” Epperson said.

“You want the machine running as much as possible,” he said, adding that “a blade should be in a material 30 to 40 percent” of the time.

He also recommended an integrated system that links a company’s Enterprise Resource Planning [ERP] systems with Computer Aided Design and Computer Aided Manufacturing [CAD/CAM].

Fralix also pointed to a future beyond sewing using new technologies such as 3-D printing.

“This will have a significant impact on the fashion industry,” he said, “Today, we can do 3-D printed nylon. It doesn’t have the soft characteristics of cotton or other natural fibers, but the thinking is there. Ten years from now, we may have developed some nano-particle fiber substances that could create 3-D garments that have the characteristics of cloth. If that happens, sewing will not die—but it will transform the industry.”