Apparel Companies Look Into Solar Power

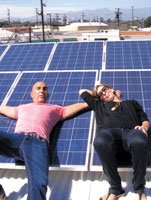

Dotan Shoham, co-owner of the Los Angeles–based Pacific Blue Dye House, a boutique facility specializing in the contemporary and premium markets, and the Gypsy ’05 contemporary knitwear label, sees infinite possibility in the sky.

“This is California. If there’s one thing we have, it’s a lot of sunshine,” he said. Los Angeles averages 329 sunny days each year—making it one of the best spots in the country for harvesting solar power, said Daniel Nazarian of American Solar Energy Solutions, a Los Angeles–based manufacturer, developer and installer of solar-panel systems for commercial, industrial and residential buildings.

In December, Shoham worked with American Solar Energy Solutions to install enough solar panels on the roof of Pacific Blue to provide 80 percent to 85 percent of its energy needs. Pacific Blue operates a 30,000-square-foot facility out of which it provides wash-house services for brands such as J Brand, Hardtail, Ella Moss, Splendid, Affliction and True Religion Swim.

Now, six months later, Shoham is insulated against rising energy costs—the Los Angeles Department of Water and Power has approved a rate hike of nearly 5 percent to go into effect on July 1—and he’s looking for more ways to use solar power.

Pacific Blue’s solar panels, which cover approximately 30 percent of the facility’s roof, will generate approximately 60,000 kilowatt-hours each year and reduce global carbon emissions by an estimated 48 tons per year.

“We didn’t do it just for the savings,” Shoham said. The solar panels, which cost approximately $250,000 and took nearly four months to plan and install, are part of the company’s attempts at being friendlier to the environment. “We’re a dye house; we’re never going to be great for the environment. It’s impossible, but we can be friendlier. That was the purpose of the solar panels. We want to be better,” he said. It will take Pacific Blue five to seven years to recuperate the costs of installing the solar panels. “That’s fine. From a pure business point of view, that might not be the best thing. But we are trying to do something different; we are trying to make a statement.”

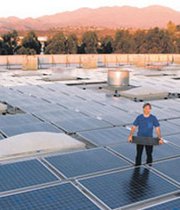

The company isn’t alone in turning to the sun for energy saving and environmental contributions. In 2003, Lake Forest, Calif.–based skate shoe and apparel company Sole Technology installed solar panels on its roof. “We were early adaptors of the [solar power] technology,” said Roian Atwood, Sole Tech’s manager of environmental affairs. Sole Tech’s solar panels produce approximately 13 watts of energy per square foot and are part of the company’s plan to be completely carbon-neutral by 2020. To achieve that goal Sole Tech has built a dedicated environmental-affairs department and has implemented a variety of measures, including working with overseas factories that are powered by environmentally friendly means. Some of the factories Sole Tech works with in China, for example, are powered by 76 percent hydroelectricity.

Pacific Blue and Sole Tech are not alone in their solar initiatives. In 2006, American Apparel became one of the first companies in the country to take advantage of a 30 percent federal tax credit for solar power.

Nazarian, who hasn’t worked with other apparel companies in Los Angeles, said solar panels can be cost-prohibitive for some, but with looming DWP rate increases, interest from the local fashion industry has spiked.

Shoham isn’t finished yet with solar power. Soon, Gypsy ’05 garments will bear tags that inform consumers that the brand’s garments are produced in a solar-powered facility. “The next project is figuring out how to convert our 4,000-gallon water tank to solar power. We have to create a new system, but it is doable and it will be incredible,” he said. Pacific Blue hopes to complete that project by the end of this year.