Central America Bets on Speedy Delivery to Grow Its Apparel Industry

GUATEMALA CITY—As Central American apparel and textile factories try to maximize the benefits of the free-trade agreement with the United States, they are learning that their one advantage is shaping up to be speed to market.

It was a phrase that was bantered about in seminars, textile tours and conversations at the 18th annual Apparel Sourcing Show, held May 19–21 in Guatemala City. This year, only 160 booths were set up at the compact show, a nearly 25 percent decline over 2008.

In recent months, U.S. retailers have been hammering away at the speed-to-market message, telling factories that consumers’ ever-changing buying habits have made it imperative to have just-in-time deliveries and goods that exude freshness and trend-driven elements.

“Our goals are speed, agility and price right now,” said Ed Massura, director of product development, juniors, at Pacific Sunwear, the mall retailer based in Anaheim, Calif. “Buyers want to pull the trigger as fast as possible.”

Massura was in Guatemala for the first time, searching to expand the number of factories his company works with for its private-label clothing sold to teen-agers.

He was particularly interested in apparel and textile companies that had factories in various countries around the world so they could offer flexibility. The retail executive was also eager to find companies from the Central American region that could provide synthetic textiles and apparel to avoid paying high duties, which can add as much as 33 percent of a garment’s value coming from non-free-trade-agreement countries, such as China.

Sydney Younger—who is with VF Corp., the corporate apparel giant in Greensboro, N.C., whose labels include 7 For All Mankind, Wrangler, Lee and Jansport—was not only concentrating on speed to market but factories that could provide full-product development and lower prices. “Buyers are under pressure,” she noted. “If we can replenish in 30 days, it helps us increase revenue.”

These messages weren’t lost on Carlos Arias, president of Denimatrix, a new blue-jeans factory located in the old Koramsa factory near Guatemala City. Koramsa, launched in 1989 with the idea of doing big orders for big brands, used to make 700,000 blue jeans a week for some of the United States’ leading retailers and manufacturers including Levi Strauss & Co. and Gap Inc. But profit margins were low, and the owners closed the factory early this year.

In stepped the Plains Cotton Cooperative Association, based in Lubbock, Tex., which in February purchased Koramsa’s assets and set up shop in the old factory. The cooperative runs the American Cotton Growers denim mill, which was a principal supplier to Koramsa and is now a major supplier to its Denimatrix division. “We are a new company with an old soul,” Arias said.

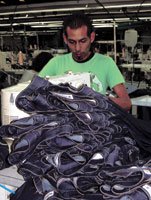

While the old factory was humongous and took up 850,000 square feet, the new operation occupies only 360,000 square feet. Its 2,390 workers are making 50,000 pairs of blue jeans a week. Denimatrix’s main customer is Abercrombie & Fitch and its Hollister brand, followed by Gap and The Buckle.

These days, 60 percent of the factory’s orders are 500 units or less. “You have to fall in love with small orders,” said Arias, who also was president of Koramsa. “We don’t want to be the largest factory. We want to be the best, focus on high fashion, high service and have customers that need a partner more than a vendor.”

He boasts that the blue-jeans factory can deliver a pair of pants to the United States, from concept to stores, in eight weeks. “We can beat China by eight weeks. By the time those containers are coming in [from China], we’re onto the next thing.”

Denimatrix’s goal is to eventually make 150,000 pairs of blue jeans a week with 4,400 workers.Changing times

Even textile manufacturers in the region are thinking differently. Many are starting to offer full-package options. Not only do they manufacture the fabric in Central America, but they also are partnering with local sewing contractors to form the garments.

One such textile manufacturer is Seung Hee Kim, president of Alcatextil. Kim immigrated to Guatemala 13 years ago from South Korea, working with his older brother until six years ago, when he launched his own company, which makes knit fabrics. Over the years, Alcatextil’s revenues have grown steadily from $4 million the first year to $9 million last year.

But last year was a rough year for the U.S. apparel and textile industry, which trickled down to Alcatextil. Several of Kim’s clients closed their doors, leaving him with $1 million in unpaid bills.

To gain more control of his business and his fabric, made on 150 knitting machines, he partnered last October with a sewing contractor and started getting orders for finished products. His first order came from Stony Apparel, the Los Angeles maker of juniors and children’s apparel. He now sews for Self Esteem, another Los Angeles juniorswear maker, and he just received his first order from Los Angeles–based giant Guess? Inc.

He expects his sewing business to add $5 million to his revenues this year. Tough competition

In recent years, Central America has been struggling to keep afloat in the apparel game, fending off low prices from China and Bangladesh and skilled sewing workers in Vietnam and Sri Lanka.

Its salvation was to be the Dominican Republic–Central American Free Trade Agreement, which took effect in 2006. It encompasses all five Central American countries—Guatemala, Nicaragua, El Salvador, Honduras and Costa Rica—as well as the Dominican Republic, giving many of their goods duty-free and quota-free access to the U.S. market.

Some countries, such as Honduras and El Salvador, have benefited, with apparel exports to the United States up for the year ending March 31, 2009. Honduras saw increases of .21 percent, and El Salvador inched up .07 percent.

Other countries, such as Guatemala and Nicaragua, weren’t as fortunate. Guatemala’s apparel and textile exports dropped 11.7 percent, and Nicaragua saw its exports decline 8.1 percent.

About 94 percent of what Honduras ships to the United States enters duty-free, while only 55 percent of the garments Guatemala sends arrive free of duty. (Duty-free status depends on fiber content and the country of origin of the fabric or fiber.)

Guatemala was particularly hard hit last year by soaring electricity prices that more than doubled in a few months. “In June last year, electricity prices went from 10 cents per kilowatt hour to 22 cents per kilowatt hour,” said Alejandro Ceballos, president of Vestex, a trade group representing the Guatemalan apparel and textile industry. “It broke a lot of apparel companies.”

That meant 15,000 apparel and textile workers lost their jobs last year in Guatemala, with 50,000 now employed in the industry, Ceballos said. With petroleum prices down, Guatemala’s electricity prices declined to 8 cents a kilowatt hour.

High energy costs forced Ceballos last summer to close his company, called Polar Industrial, and lay off 1,300 workers. They made polo shirts, T-shirts and fast-food uniforms. He has returned with a smaller organization, called 3 Pro Produccioacute;n, which basically makes the same garments working with subcontractors.

Guatemala also faces the challenge of higher labor costs. Guatemala’s minimum wage plus benefits averages $213 a month, compared with $176 a month in El Salvador and $118 a month in Nicaragua. The Guatemalan government is working on a plan to change the $8-per-day minimum wage for garment employees, who must be paid that rate whether they put in eight hours a day or two hours a day, to $4 a day plus up to a $4-per-day bonus for 100 percent completion of the day’s production. It is expected to go into effect Jan. 1, 2010.